X-ray stress analyzer

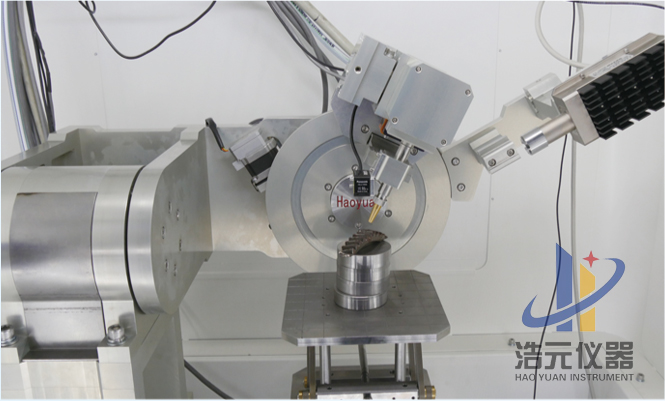

DST-17 X-ray Stress Analyzer

The DST-17 X-ray stress analyzer provides the most reliable means of testing materials and their products. Residual stress and texture can be accurately measured for multi-domain material structures and irregularly shaped parts.

The instrument is characterized by high power, high resolution and accurate measurement results.

Performance description

Performance description

High-precision diffraction angle measuring device for the most accurate 2θ angle

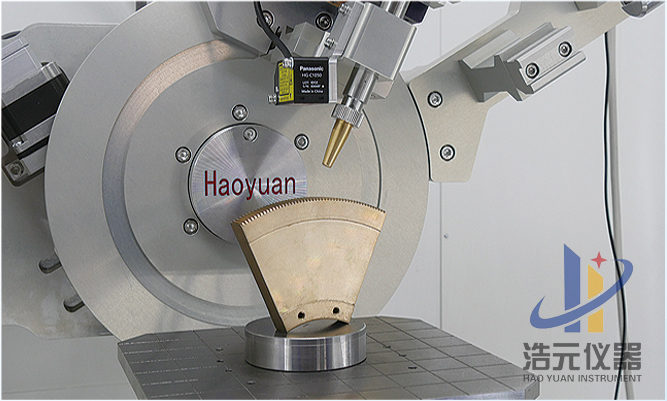

Both iso- and side-inclination methods can achieve residual stress

Automatic conversion of stress measurement in the X and Y directions at the same point to achieve tangential stress measurement

Arbitrarily set the point of sample, automatically complete the residual stress measurement, and draw the stress distribution map

High-resolution SDD detector for residual stress measurement of various materials when the target is fixed

Simultaneously configure Si drift line array detector to quickly complete residual stress measurement

α angle range is large, measure pole figure by side-inclination method

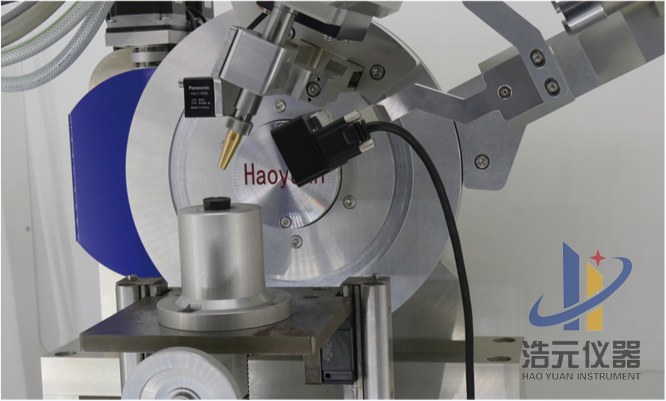

Built-in laser ranging locator for automatic positioning of samples with repeatability less than 3μm

CCD camera, laser calibration, 5D hand crank control, simplify manual positioning

|  |  |

| High resolution SDD detector | Si drift line array detector | Si drift line array detector |

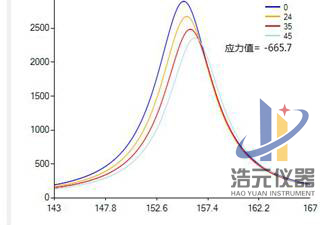

The instrument realizes intelligent control, quickly completes residual stress measurement, and is easy to operate.

|  |

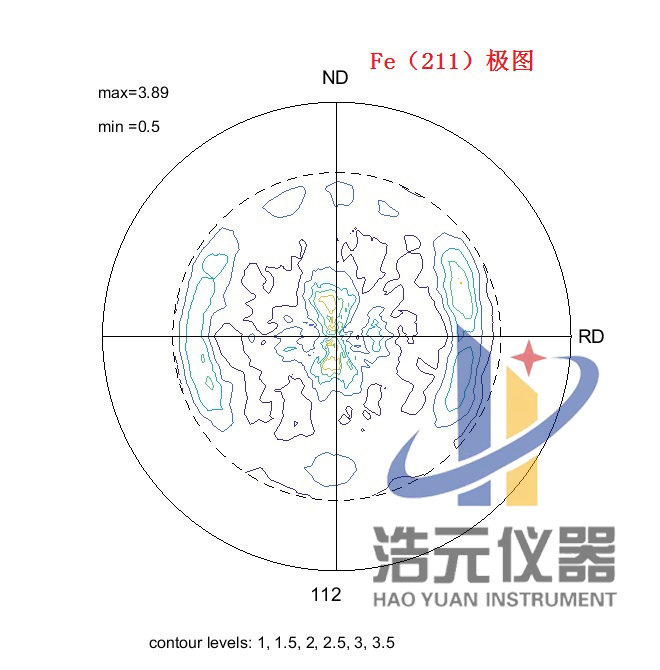

| Residual stress measurement | Fe (211) Pole Figure |

The complete data processing software can edit the Miller index and Young's modulus Poisson's ratio calculation parameters to achieve accurate calculation of residual stress, half-width and austenite content. Professional software completes texture calculation and draws pole figures.

Technical parameters:

| 2θ angle range | 110°—170° |

| Ψ angle range | 0—60° |

| Ф angle range | 0—360° |

| α angle range | 0—70° |

| 2θ angle resolution | Minimum to 0.01° |

| X-ray tube voltage | 10—60kV |

| X-ray tube current | 5—50mA |

| Stability | <0.005% |

| Cermet X-ray tube | Various targets such as Cu, Cr, Fe, Ti, V, Co, Mn, etc |

| Radiation round spot | 0.2, 0.5, 1, 2mm |

| Rectangular spot | 0.5×3, 0.5×5, 1×3, 1×5, 2×3, 2×5mm, etc. |

The product complies with ASTM E915-2010, and EN 15305-2008 and GB7704-2008 residual stress analysis and testing standards, and the production process meets the requirements of ISO 9001 quality management system.